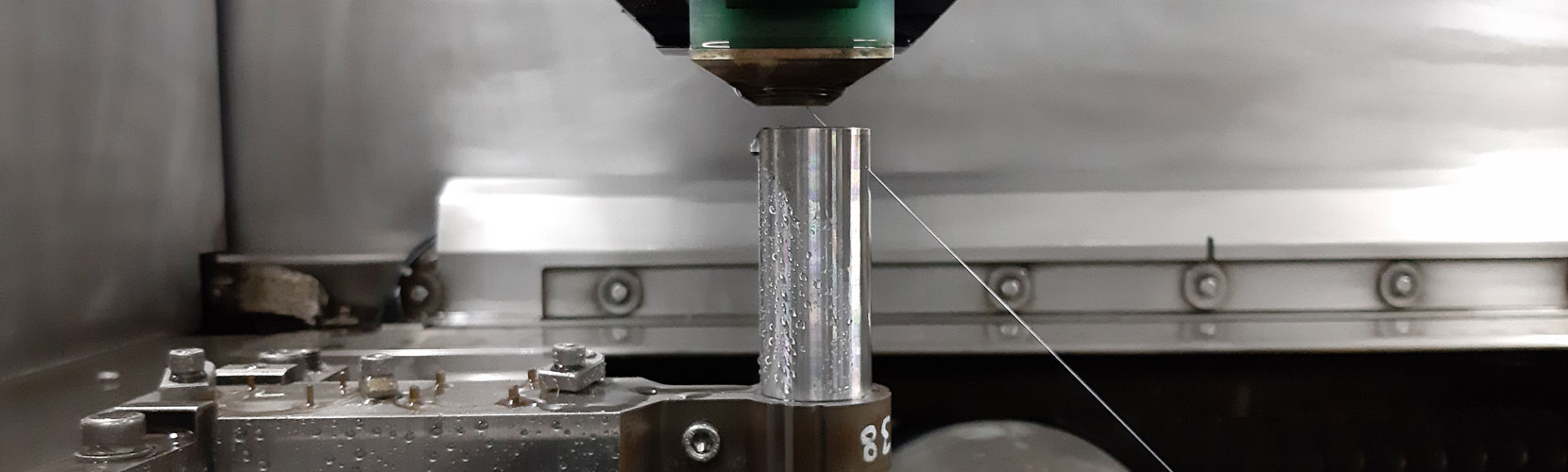

Wire EDM with state-of-the-art machines – for the highest precision and quality.

Reliable, on-time, and up-to-date with the latest technology.

Our wire EDM service stands for the highest precision and quality. With state-of-the-art technology and years of experience, we offer customized solutions for your demanding projects. Our advanced machines, such as the Agie Cut Progress, ensure top-notch surface finishes up to Ra 0.2. Thanks to automated processes and flexible working hours, including weekends, we can meet even time-critical deadlines. Rely on our expertise and request your personalized quote today!

Wire EDM machines

Our extensive selection of wire EDM machines – including the Cut P 550 Pro, AC Progress VP4, AC Progress VP3, and AC Progress VP2 – provides you with maximum flexibility and precision for your projects. Each machine is designed to deliver the highest surface finishes and accuracy, allowing us to meet your individual requirements optimally.

Cut P 550 Pro

| X/Y/Z Axes (mm) | 550 x 350 |

| Rapid Traverse X/Y | 3 m / min |

| U/V Axes (mm) | 550 x 350 x 400 |

| Max. Cone Angle/Height | 45° / 400 mm |

| Dual Measurement System | Glass scales |

| Max. Workpiece Dimensions (mm) | 1000 x 700 x 400 |

| Max. Workpiece Weight (kg) | 1500 |

AC Progress VP4 (2x)

| X/Y/Z Axes (mm) | 800 x 550 x 525 |

| Rapid Traverse X/Y | 3 m / min |

| U/V Axes | 800 x 550 |

| Max. Cone Angle/Height | 45° / 500 mm |

| Dual Measurement System | Standard |

| Max. Workpiece Dimensions (mm) | 1300 x 1000 x 520 |

| Max. Workpiece Weight (kg) | 3000 |

AC Progress VP3 & AC Progress 3

| X/Y/Z Axes (mm) | 500 x 350 x 426 |

| Rapid Traverse X/Y | 3 m / min |

| U/V Axes | #70 |

| Max. Cone Angle/Height | 30° / 100 mm |

| Dual Measurement System | Standard |

| Max. Workpiece Dimensions (mm) | 1600 x 650 x 420 |

| Max. Workpiece Weight (kg) | 400 |

AC Progress VP2 & AC Progress 2

| X/Y/Z Axes (mm) | 350 x 250 x 256 |

| Rapid Traverse X/Y | 3 m / min |

| U/V Axes | #70 |

| Max. Cone Angle/Height | 30° / 100 mm |

| Dual Measurement System | Standard |

| Max. Workpiece Dimensions (mm) | 750 x 550 x 250 |

| Max. Workpiece Weight (kg) | 200 |

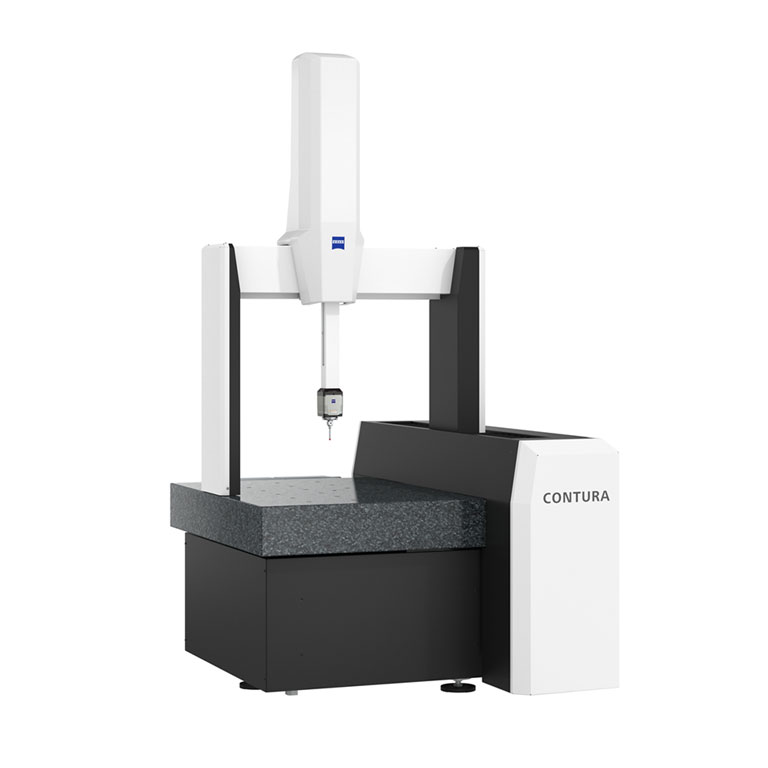

Measuring machine Contura 2G

The Contura 2G measuring machine from Carl Zeiss Messtechnik GmbH is currently equipped with the Calypso 2019 software and the VAST XT probe. The probe allows for scanning a variety of contours. By importing 3D data (e.g., STEP models), a comparison can be made between the desired and the eroded shapes.

Additionally, individual workpieces are measured on the mounted reference system with the installed Preset Module (as of 2019) to transfer the measurement data to the respective wire EDM machines.

Technical Data

| Width (mm) | 1430 |

| Height (mm) | 1830 |

| Length (mm) | 2800 |

| Measuring Range | Standard |

| X (mm) | 700 |

| Y (mm) | 1000 |

| Z (mm) | 600 |

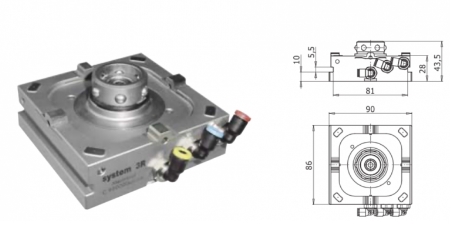

Automation (Work-Pal 3R-System)

Achieving efficient production with wire EDM machines involves several components. A comprehensive clamping and reference system is crucial. We use Unimatic pendulum plates and System 3R clamping elements. Workpieces are aligned parallel to the axes on a presetting station and measured on the Zeiss CONTURA 2G measuring machine.

The measurement data is transferred to the wire EDM machines. Measured workpieces are then placed on the pallet stations of the Work-Pal robots (System 3R).

With the reference system and pneumatic clamping chucks on the machine table, a solid foundation for automation is created. The Work-Pal robots, connected with the AgieCut Progress 2 machines, enable a fully automated production cell that can handle up to 12 pallets independently. This eliminates time-consuming setup processes, minimizes downtime, and optimizes machine capacity. As a result, we can perform wire EDM faster and more cost-effectively.

Unimatic pallet holder C 950 000

We optimize our manufacturing processes with the Unimatic pallet holder C 950 000. This allows for fast and precise positioning of your workpieces, ensuring maximum efficiency and productivity.

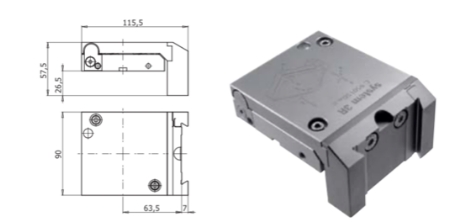

Set Unizero Go! S112 050

With the Unizero Go! S112 050 set, we enhance your manufacturing efficiency. We provide optimal workpiece clamping for precise results and quick setup times in your production.

Unimatic pendulum pallets (C950 150 & C951 150)

We use the Unimatic pendulum pallets (C950 150 & C951 150) for flexible and precise workpiece processing. This ensures efficient handling and high repeat accuracy in manufacturing.

Manufacturer: Huber GmbH & CO. KG, Gustav-Weißkopf-Straße 11, 90768 Fürth

Start hole drilling machine (River 600 CNC)

With the River 600 CNC start hole drilling machine, we provide precise and efficient drilling for your projects. Its modern technology allows us to create highly accurate start holes quickly and reliably, reducing your production times and enhancing quality.

Technical Data

| Travel Paths X/Y (mm) | 600 x 400 |

| Travel Path Z (mm) | 300 |

| Max. Workpiece Height (mm) | 400 |

| Max. Workpiece Weight (kg) | 800 |

| Machine Dimensions (mm) | 1000 x 1500 x 2300 |

Rotary and indexing spindle

Rotary and indexing spindles are used on wire EDM machines. They offer a cost-effective alternative to hard turning or fine grinding. Small parts (pins, needles, etc.) made from stainless steels, hard and non-ferrous metals, as well as conductive ceramics that can no longer be manufactured conventionally through turning, grinding, etc., can be efficiently produced using these spindles.

The rotary/indexing spindles from Carl Hirschmann GmbH provide not only high-speed rotation but also precise indexing and simultaneous processing (controlled by the machine). This enables the erosion of fine rotationally symmetric structures, as well as precise surfaces and contours.